No one is ever let into the Tata Motors plant at Sanand but for its staff and to know I was going to be visiting it in a short while was very exciting. As I had said earlier, I had seen the Nat Geo documentary of the plant and I felt very special and proud to have got the opportunity to be #TheChosenOne and get to see everything happen right in front of me. It was indeed surreal.

It was 7th July,2015, The day had finally come where we will get to see the award winning Tata Nano plant in Sanand. We were told to report at the lobby by 9 o clock with our cap and tag where we would be taken in a bus.

After a good breakfast at the hotel, I went to the lobby to see everyone waiting to board the bus. Meanwhile, I interacted with few of them and of course all of us became friends and it was great to see everyone excited to visit Sanand.

The road to Sanand

Once the bus was ready, we boarded the TATA bus and started to Sanand. It was about 30-40 km drive from the hotel where we were staying. I chose the window seat and that gave me an opportunity to see Ahmedabad at least the little I could manage . It was interesting to see the well maintained roads, tall buildings on the highway and of course very smart traffic system unlike other cities.

After a good long drive, We reached Sanand estate 2. A little further inside was the Tata Nano plant. The first impression of the entrance at the gate was majestic. As the security officers opened the gates, the first view inside was pleasantly surprising, there was a lot of greenery all around.

Welcome #TheChosenOnes

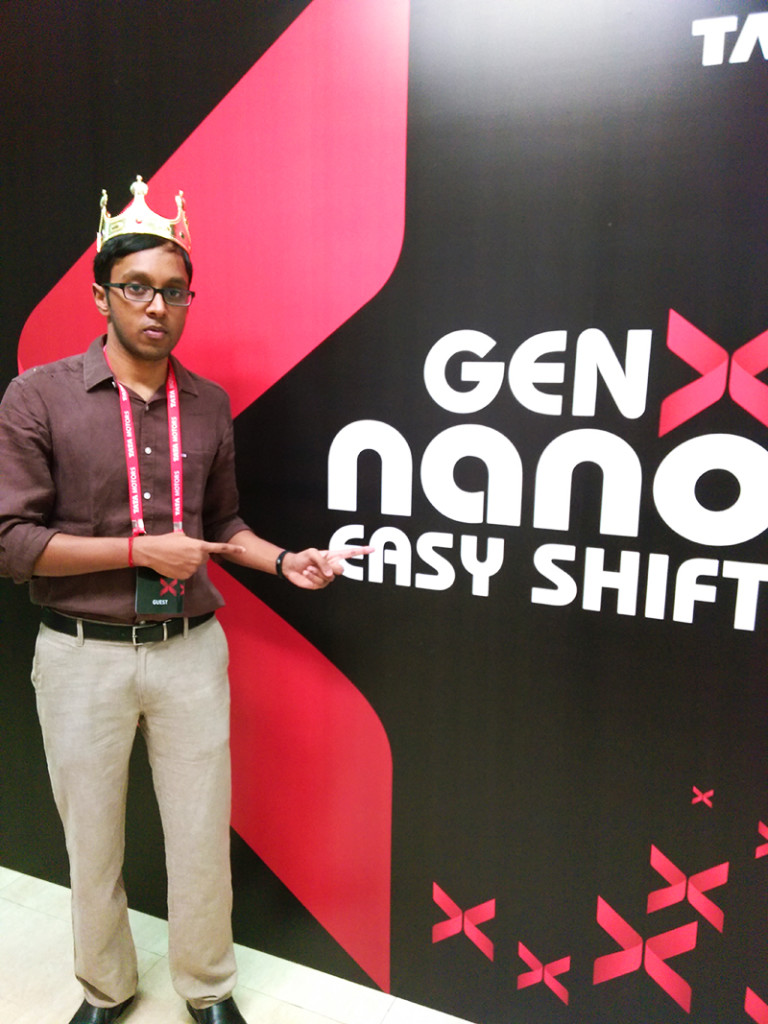

We drove further inside where there was a huge flex that read, ‘Welcome #TheChosenOnes’. A red carpet was laid just like how a movie premier happens with many photographers and videographers standing beside. We got down from the bus and there was Hoezaay welcoming all of us at the red carpet with the confetti’s being discharged all over. There were so many confetti’s discharged that by the time it was done, half my body was covered with those colour papers. It was paparazzi all around and as we walked further, we were crowned by the Tata Motors team and of course royal treatment given by them. This clearly showed the interest of Tata Motors to make sure that every #TheChosenOne was made to feel very special in every way possible and proving that ‘the customer is the king’. It was amazing to see the kind of effort they had put in it.

As I walked further there were couple of employees welcoming all of us and directed us to the ‘Nano’ room where we were asked to wait. We were to be briefed about the terms and conditions of the plant. I entered the ‘Nano Room’ which was neatly setup with a stage. It is basically their conference room where they address the press and media.

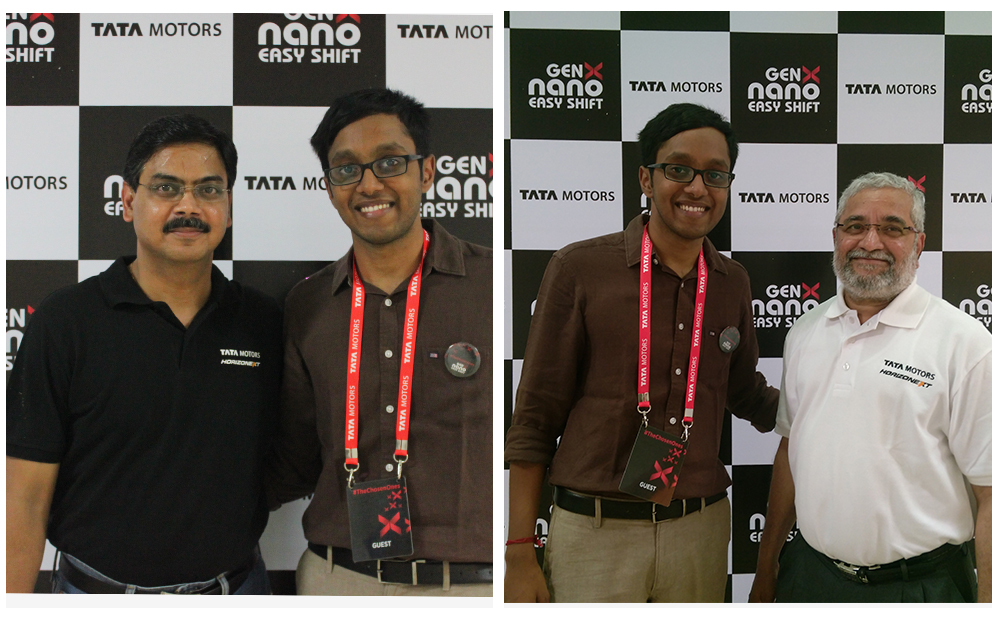

Once all #TheChosenOnes entered and settled down, there was Hoezaay once again taking the stage. He was joined by the head of marketing, Tata Motors – Delna Avari who welcomed all of us and told us about the Do’s & Don’t at the plant. She next invited Mr.Girish Wagh, the Vice President of Tata Motors and the man who has been with Nano ever since its inception and knows the history behind it.

Many years ago, I happened to see Mr. Ratan Tata’s interview at the Columbia Business School on a particular incident that made him make a dream into reality by creating the world’s least expensive car.So here is the story of it as told in the interview.

The story of Nano

Mr. Ratan Tata happened to see a family of 4 on a 2 wheeler where the father was riding with one child sitting in front and the wife behind with the other child on her lap, it was raining and so they were taking cover under a bridge. He felt it was totally unsafe to travel like that and that was the first instance where he had an urge to do something to the people in India about travelling safe. One day while driving in Bangalore, a family fell down right in front of his car and were injured with minor bruises. At that moment he thought he must start working on a car that could be affordable and also provide a safe medium of transportation. Thus the Nano was a result of that.

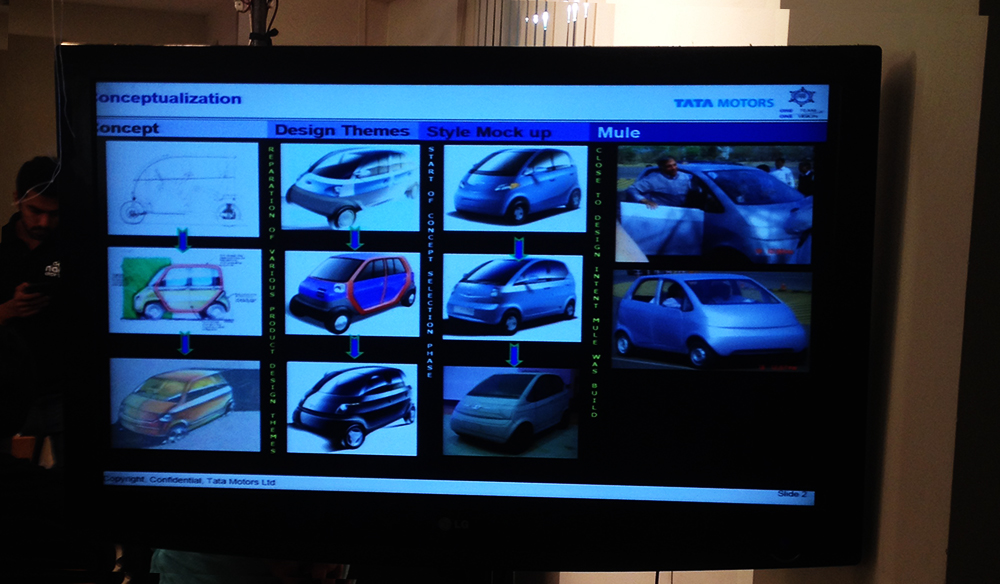

While Mr. Girish Wagh told us the history of the car right from its first prototype, he also told some about how evolution of its design and how features were added to the Nano.

Thanks @vidsury for the video

Nano Design

The picture tells you how the design for the Nano evolved. It was also told that Mr. Ratan Tata was personally involved in the design elements of the Nano.

Here are some more interesting facts

- Look of the car redesigned thrice

- Wiper redesigned 5 times

- Floor redesigned 10 times

- Since they were running out ideas for its seats, Mr. Ratan invited them to take inspiration from his chopper and thus the seats of Nano were designed.

- Advanced structural stability for ensuring safety

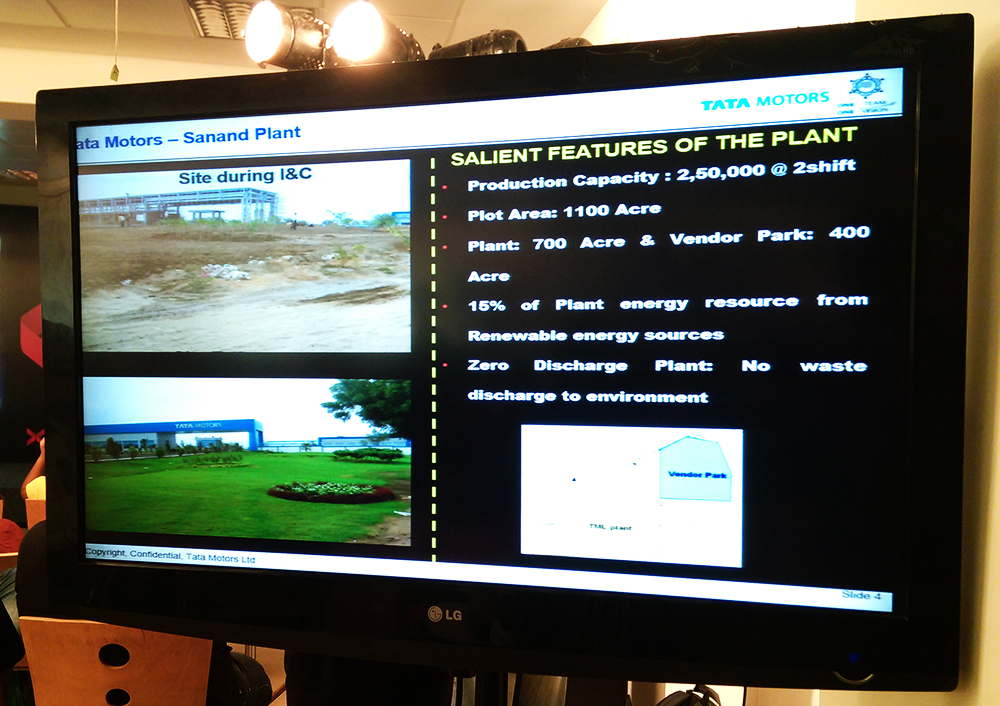

Once Mr. Girish Wagh was done, Mr. Hemanth Kulkarni, the plant head, told us some interesting facts and information about the Sanand Plant.

Tata Motors Manufacturing Plant

There were about 27 plant designs made in order to manufacture the world’s least expensive car. Out of the 27, 3 got shortlisted and from that 1 design was approved to be setup. Earlier, Mr.Girish Wagh also said that he had visited various plants of other luxury car manufacturers like Aston Martin to get an idea on how a world class manufacturing plant can be established to produce the world’s least expensive car. So once the plant was finalized, it took 24 months to set up the state of the art manufacturing facility at Singur in West Bengal.

Shifting the entire plant from Singur to Sanand

After its completion and while it was all set for production, there was some agitation, uncalled for protests and political unrest that they had to move out of West Bengal. Now, the bookings for the Nano were in full swing and suddenly they were left without a manufacturing plant. At that point of time,the then, CM of Gujrat, Shri. Narendra Modi invited Mr.Ratan Tata to move the factory to Sanand in Gujrat providing all the facilities required. Within 3 days land was allocated and the work to build a new manufacturing plant started. Coincidentally the land provided to them at Sanand was the very same land that J.R.D Tata had given to the government of Gujrat in the 1900’s. After almost over 100 years that very same land has come back to the Tata’s and would be the home of Tata Nano. While their new manufacturing plant was being setup, the production of Nano’s started happening at the Tata Motors plant in Pune. The shift wasn’t definitely an easy one, Imagine to relocate from one part of the country to the exact opposite direction, west to east, with machinery worth millions and a factory that costed over millions to setup, it needed something extraordinary to make this possible. They went ahead and actually made it a reality by transporting 100 trucks everyday. In total, there were 3600 trucks that transported all kind of machinery and equipment’s from Singur to Sanad. It took them 14 months to re -establish the manufacturing plant in the same way how it was at Singur.

Facts about Sanand Manufacturing Plant.

- Spread over 1100 acres

- The plant itself has 27 patents to it.

- It has won several awards for its design and the use of latest technology in manufacturing

- 15% renewable and solar energy is used.

- The plant uses zero liquid discharge which means no waste water goes out, it gets recycled.

- It has a 50 acre lake with over 17986 trees planted.

- A production capacity of 800 cars per day

- Every 59 seconds a Nano can be produced

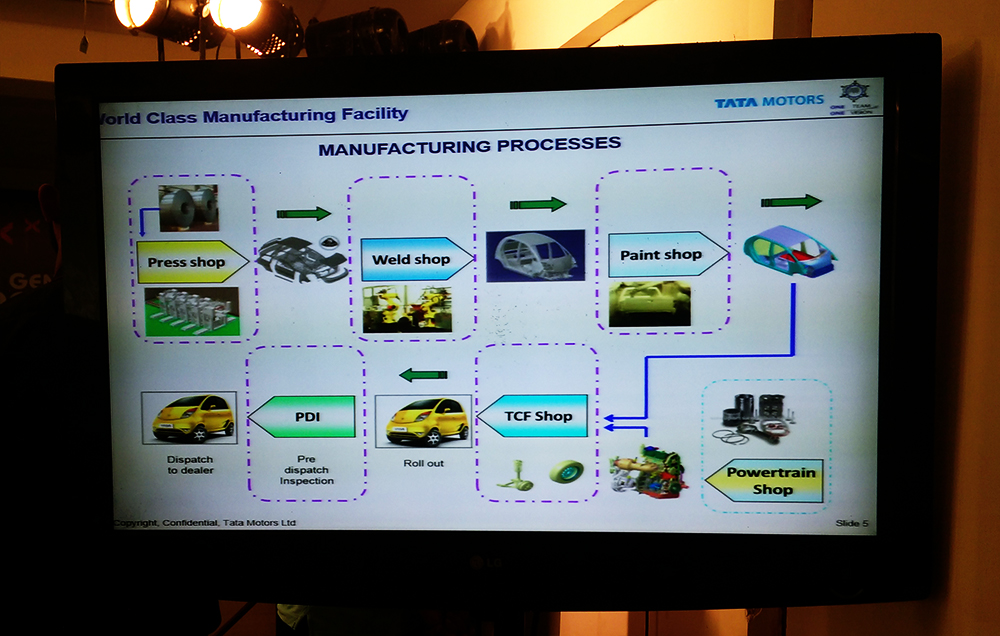

The Manufacturing Process

This is the working process by which a Nano is produced.

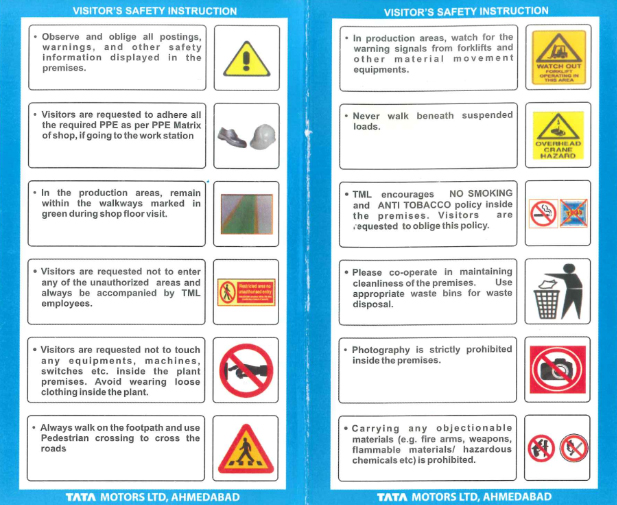

Mr.Hemanth Kulkarni joined in and shared the working process at the plant and also told us the safety instructions that had to be followed.

Safety Instruction to be followed

Once Mr.Girish & Mr. Hemanth were done with their briefing, it was time to see everything happen in front of us.

The Plant Visit

Tata Motors Marketing Team – Ms.Shruthi & Ms.Delna along with Akshit (Wizceaft) assigning the Aria cars for the plant visit.

Ms. Delna Avari assigned Tata Aria cars that would take us to the various departments in the factory. It’s a 1100 acre factory so we obviously had to commute by the cars. As we left the Nano room, we had to wear helmets and we were briefed earlier that a closed toe shoe was mandatory to enter the factory. After wearing our helmets, I walked out to the road were the Aria cars were waiting. There were around 10-15 Aria cars assigned and I was in Aria car number 9. I went to the assigned Aria car and a Tata employee welcomed me into the car. Every Aria car had a driver and a Tata employee assigned to explain the various process that takes place at every stage. I should say that the planning here was excellent to the point of detail that every 3rd person had a Tata motors employee with them to reach out to in case of doubts or help. Once everyone were ready, the cars started to move in a convoy, it looked majestic like how the politicians travel. Imagine close to 15 cars travelling in sequence at a same speed and maintaining proper distance between them. After a 10 minute ride, we reached the first point of the manufacturing process.

Press Shop

This is the first seed of the Nano where the sheet metal is pressed, cut and shaped with the high end technology. The latest technology available in the world is used to make these shapes with precision and accuracy. Since this process has patents we weren’t allowed to take pictures but the machines were really huge. Once it is shaped, it is inspected and then advances to the weld shop. There is no human intervention in the process at all, it is all robotic. It passes through the huge conveyor belts for over 400 metres to the weld shop which is the next building. Sitting inside the car, we were able to see the entire process that happened at the press shop.

Assembly Shop

Weld Shop

As I entered the weld shop, I was stunned to see the giant huge robots. They were really massive and their movements were just like humans. They were futuristic robots that worked in a pre sequenced process to form the body of the Nano. In short, the Nano is given its body right here. This was the first time I saw a robot work at this large scale, imagine if transformers were real and keeps switching their forms. I was speechless looking at the way these robots welded the car and gave it the shape. They were all imported from Japan and are patented as well, hence no pictures here too. Standing in front of it, I literally looked like an ant. It was incredible to see how they worked to give the Nano the body, technology used at its best. One has to actually be there in person to really know how amazing they function, any adjective would do injustice to it. Once the body is shaped, it passes on the sky bridge to the paint shop.

Paint Shop

This is the place where the Nano gets beautified with a distinct colour. There are about 7 unique and beautiful colours that are given to the Nano to suit different tastes accordingly. They are Sangria Red, Damson Purple, Royal Gold, Dazzle blue, Pearl White, Metro silver, Persian Rose. Once it gets Its colour, it moves through the sky bridge to the next shop which is the TCF (Trim, Chasis & Finish) hub. Photography isn’t allowed in the weld and paint shop and so couldn’t take any pictures.

TCF SHOP

This is the place where the Nano gets its heart and soul. It is here that the Nano is put together as one. Since the hardcore work happens here, this phase was really huge and one thing I loved the most about this place was the fact that there were lots of inspirational quotes placed at frequent intervals and most of them emphasized on two things. One was Team Work and other was to deliver product of highest quality with 0 defects. In this phase, first the wiring harness installation happens through an intricate process by the experts who connect them together. Then the fuel tank, dash board and the steering wheel is fixed. Then the most integral part, the engine is fixed into the Nano along with additional features like the all new Easy Shift (AMT) and ePAS (Electric powered assisted steering). Then it passes through the conveyor belt to the next phase where the tyres and alloys are put together. The next addition to the Nano are the new smoked headlamps, Infinity Motif grill bumpers and the stylish interiors to make it look sleek. Then there is the Amphistream music system along with the digital information display that is added.

Testing Time

Now, the Nano is complete as a whole and is going touch the ground for the very first time from the conveyor belt that had carried it all along. Once it touches ground, it goes through a series of tests like roller test, brake test, shower test to ensure everything is working to perfection to world class quality. After the tests are over, Experts now check every minute detail of the car from the seating to the tyre to the accessories to the engines. Once everything is approved the WCQ (world class quality) stamp is now put on the screen.

Quality Check

Now, once the WCQ is stamped, it goes for a thorough quality check once again by the experts and made sure it is all set to face the world. Once again every minute detail is rechecked to perfection in every aspect of the car. Then, for the very first time it rolls out from the delivery shop and faces the light after being polished to perfection along with the technical expertise and great craftsmanship.

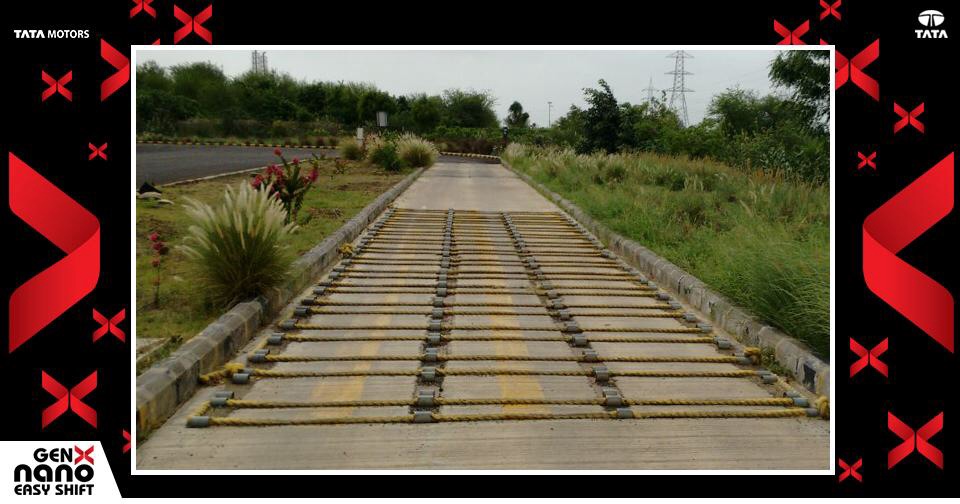

Torture Track

No, it isn’t ready yet, now the Nano undergoes a series of process in the torture track where the Nano is tested for its stability and sturdiness on the road where a lot of hurdles have been placed on it. To understand better, it is checked to suit the Indian road conditions where speed breakers, pot holes and so on are placed on the road. Then the most amusing part for me was when the Nano was tested inside a bridge with water upto a feet and a half to test the water level conditions of the Nano. It passed through it without any hassle. After it is tested here, it is taken to the Infinity track.

Infinity Track

It is here that the fully approved Nano is taken for a spin to test its smoothness and comfort.

Now after passing all this successfully, the Nano is ready to roll out to the world.

There is nothing called as small accident

These were the exact words found in most of the places.After coming out of the Assembly shop, one thing I noticed is that SAFETY is their utmost priority at any cost for their staff and anyone inside the plant. There is a safety board that is put up every 40 metres so that you know you can’t take things lightly. No one is allowed inside without helmets and closed toe shoes. There are specific green markings on the floor on only which people should walk and they are very serious about it too.

Delivery Hall

After getting to know the interesting production process, we were taken to the delivery hall in a bus. In this delivery hall, the Nano is officially sent out to the dealers. Now at the delivery hall, #TheChosenOnes were to be surprised. The hall was neatly setup like the ones you usually see during the car launch.

#GenXNano

Incase you didn’t know, the #GenXNano is the latest offering from Tata Motors that boasts of advanced performance, comfort and design.

What is new about the #GenXNano?

- Easy shift gears (AMT)

- Spacious interiors

- Improved design

- Advanced structural stability for enhanced safety

- Epas (Electric power assisted steering)

- Bluetooth powered music system

- More luggage space with external boot

I am #GenXNano

#GenXNano rolls out for #TheChosenOnes

We assembled in the hall and we were given refreshments and there was Hoezaay once again with the mike who welcomed us back after the amazing visit to the plant. And the surprise was that #TheChosenOnes who had booked their Nano’s are going to see their car for the very first time at its very birth place and a birth certificate would be given to the parents (owners). Each car had been named by the customer at the time of booking and so right from the time, the production process started, it went to production under the given name. As Mr.Girish Wagh pressed a button, the doors opened and there were the Nano’s lined up to be handed over to their respective owners. So every family that had come received their brand new #GenXNano with its key and birth certificate from Mr.Girish Wagh, Mr.Hemanth Kulkarni and Ms.Delna Avari. All the #GenXNano owners felt elated and really proud to receive their car from its birth place. I mean, how many people would get the opportunity to see their car being manufactured right from a sheet of metal to a full fledged advanced car to drive? They felt happy and equally emotional. I also did feel a sense of pride in all of them in owning a Nano after seeing the entire process.

The Lake Visit

After their Nano’s were handed over, we headed for a big group family photograph at the parking bay. We then headed next to a whopping 50 acre lake that had been made. There was a lot greenery all around and it has around 17,986 trees of 10 varieties. It is also a home to several migrating birds.

The Cafeteria

After the lake visit, we boarded the bus for lunch. We were taken to the cafeteria where our lunch was served. Their dinning hall looked huge and had ice cream centers to it as well. It was a buffet and all of us enjoyed a good meal after an eventful plant visit. A cake was cut and as I had mentioned, I love desserts, I did taste the truffle and it was one of the best I had ever tasted.

Awesome Goodies to take home

Once lunch was over, while moving out, we were given some really awesome and cool goodies from the Tata Motors team, they really pampered all of us to the very best they could, I must admit. What was inside the bag? It was a T-shirt, selfie stick, yummy chocolates, the group photograph that was shot moments ago and all those that you see in the picture. I got my share of goodies and boarded the bus back to our hotel by 4.30 as many of them had their flights to catch that very night.

While heading back, I was recollecting all that I had seen from morning and was still in awe of the entire process and the Sanand plant. Imagine the kind of effort that would have gone into setting up this plant not once but twice. The Sanand plant also has won many accolades and awards for its design and infrastructure alone. To have seen something of this magnitude and to know that it is an Indian company, it is a very proud feeling and I also did hear a lot families say how they were spellbound after seeing the mega plant. To be very honest, the moment I walked into the TCF chamber and seeing everything function, I had Goosebumps. A huge salute to Mr.Ratan Tata’s vision to produce the world’s least expensive car in a factory that has the most advanced technology and the best of everything culminated in it. Incase many of you didn’t know, Tata Motors are the only automobile company in the world that produces world’s least expensive car and one of the world’s most expensive car in the form of the JLR (Jaguar Land Rover) company that produces the Jaguars and the Range Rovers which are also owned by them.

I say it again,No one has ever been allowed inside Sanand and to have got the opportunity to go inside and have a live experience of the entire plant and the process, I feel and privileged and blessed to have been a part of #TheChosenOnes campaign. I own a Nano Twist and I feel really proud to own a Nano.

To sum it up, the entire #TheChosenOnes campaign was nothing short of excellent. The hospitality provided by the Tata Motors was incredible. A special mention of the Wizzies Akshit Vyas,Keyur, Snigdha Sharma and the entire team at Wizcraft who were responsible for organizing and managing the events. They couldn’t go wrong anywhere. Right from the picking up the guests at the airport to a comfortable stay at Novotel, taking all of us to Sanand and giving us an amazing reception at the plant and then to getting us back to the hotel and then dropping us back at the airport they were spot on. The Tata Motors team ensured that every guest was made to feel special and I must say they were very successful in doing that.

The awesome digital team of Tata Motors L-R (Priyanka,Ashish) the bloggers (Karishma,Bhushavali,Raza,Shreenidhi) with Hoezaay)

Thanks Tata Motors for this amazing opportunity, made a lot of new friends and have lots of memories from this wonderful experience that I will cherish for the longest time to come.

Click here to know more about how Day 1 turned out for #TheChosenOnes

[Best_Wordpress_Gallery id=”8″ gal_title=”More to see”]

What an absolutely delightful post, Raja! The photos are awesome and so is the descriptive narrative! It was wonderful to meet you at this unforgettable event!

Cheers!

Thank you so so much once again Vidya maam. As I had said earlier it was great to have met you as well. One of the sweetest and genuine people I have come across. 🙂